Automation Case Study: S3DEL

Inovance automation products chosen for micro machines

French OEM uses multiple compact Inovance products for high-spec micro machines.

S3DEL

S3DEL is a French manufacturer and seller of micromachines and equipment for various industries such as jewelry and dental. The company specialises in creating tailor-made solutions that fit the specific needs of its customers.

The Challenge

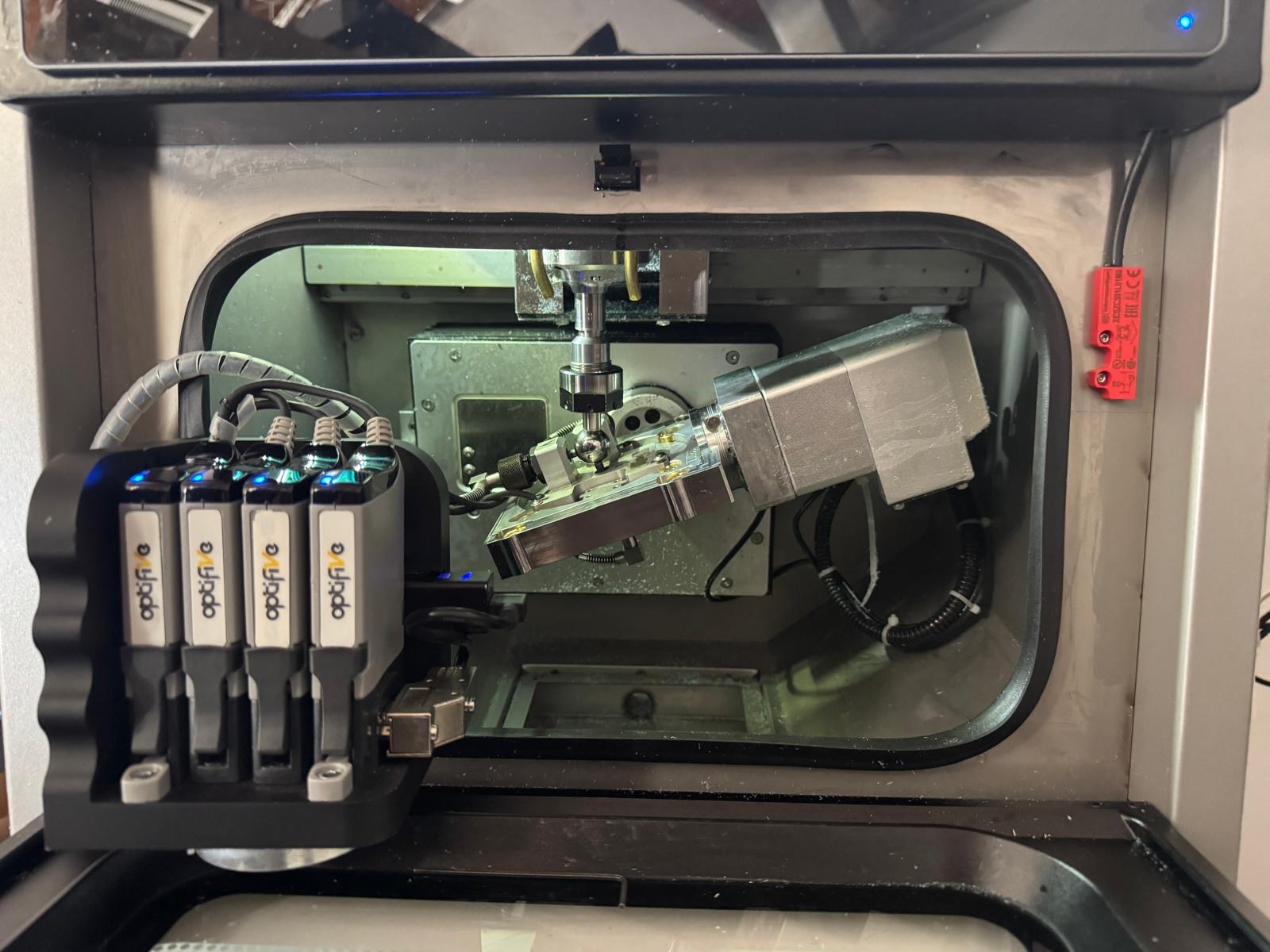

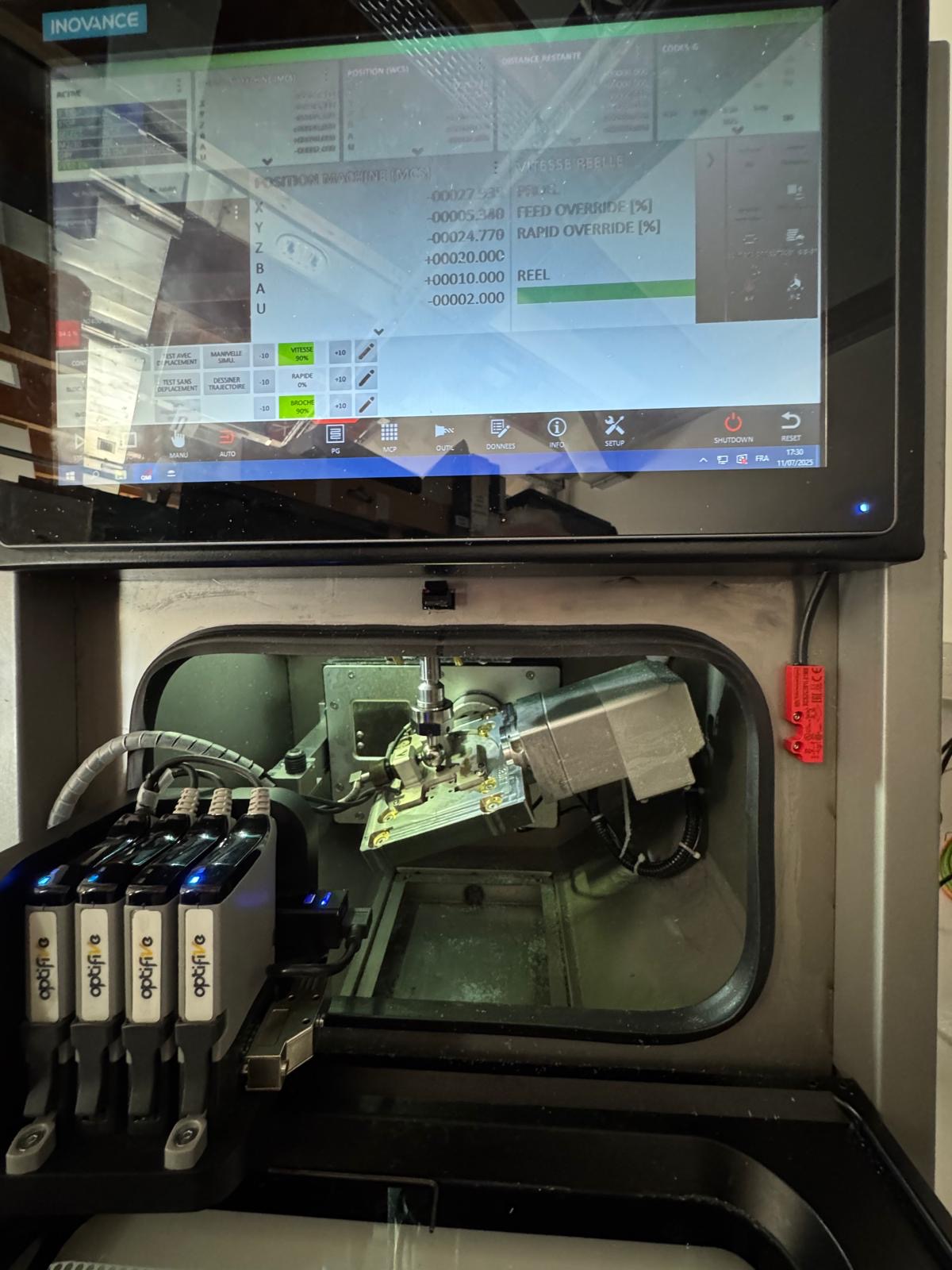

S3DEL created a 5-axis machining micromachine, weighing only 120kg, offering the same technologies and functionalities as machines used across the heavy duty industry. The biggest challenge was fitting all the electrical components into such a small space without compromising on performance. Other issues the company considered before choosing an automation supplier were energy efficiency, precision and speed of motion control, and communication and ISO code interfaces. Product availability was a critical factor as S3DEL needed the components to be sourced quickly. Finally, S3DEL needed to feel confident its supplier had a strong on-the-ground technical team in France who could help as needed.

The Solution

After a thorough survey of the market, S3DEL decided to work with Inovance. The company used a wide range of Inovance products to help meet the size and performance requirements of their micromachines. Products used included:

- The PA9000 CNC, an ultra-compact EtherCAT CNC control offering real five axis technology (RTCP), that is lightweight, rugged and ideal for small machines.

- The SV660N, a servo drive that delivers highly dynamic performance in a small footprint.

- The MS1 servo motor, a highly dynamic range with multiple power ratings and a compact footprint.

- The MD200, a compact, high frequency open-loop AC drive.

- A range of other more peripheral Inovance products such as I/O modules and line filters.

Interested? Contact our sales department

The Benefits

Inovance’s products have reduced energy usage because the machine now runs on 220V instead of 440V. Other benefits include reduced dimensions and weight, and the machine is now far easier to move and manipulate. Beyond the financial savings, S3DEL also values the reduced carbon footprint that these benefits have resulted in.

Installation and commissioning was also a major success. This was a complex project with a tight timeframe but there were no major issues and S3DEL said the strong collaboration with Inovance’s engineers was an important factor in this.

Damien Chambrey, Managing Director at S3DEL, says: “The collaboration with the engineering team at Inovance was a major factor in the success of the project. Each person involved put in 200% effort. We are pleased with the outcome and we will definitely consider working with Inovance on future projects.”

Cedric Pujols, Country Manager at Inovance Technology France, adds: “We thoroughly enjoyed working with S3DEL on this exciting project. We were impressed that the company takes more than just the bottom line into account – they have a major commitment to also cutting carbon emissions. We very much hope to continue working with S3DEL in the future.”

Key Benefits

- Reduced energy usage

- Reduced size

- Reduced machine weight

- Strong technical and engineering support

Inovance is a global industrial automation company. Visit www.inovance.euto learn more.